INVERTING THE UNWANTED

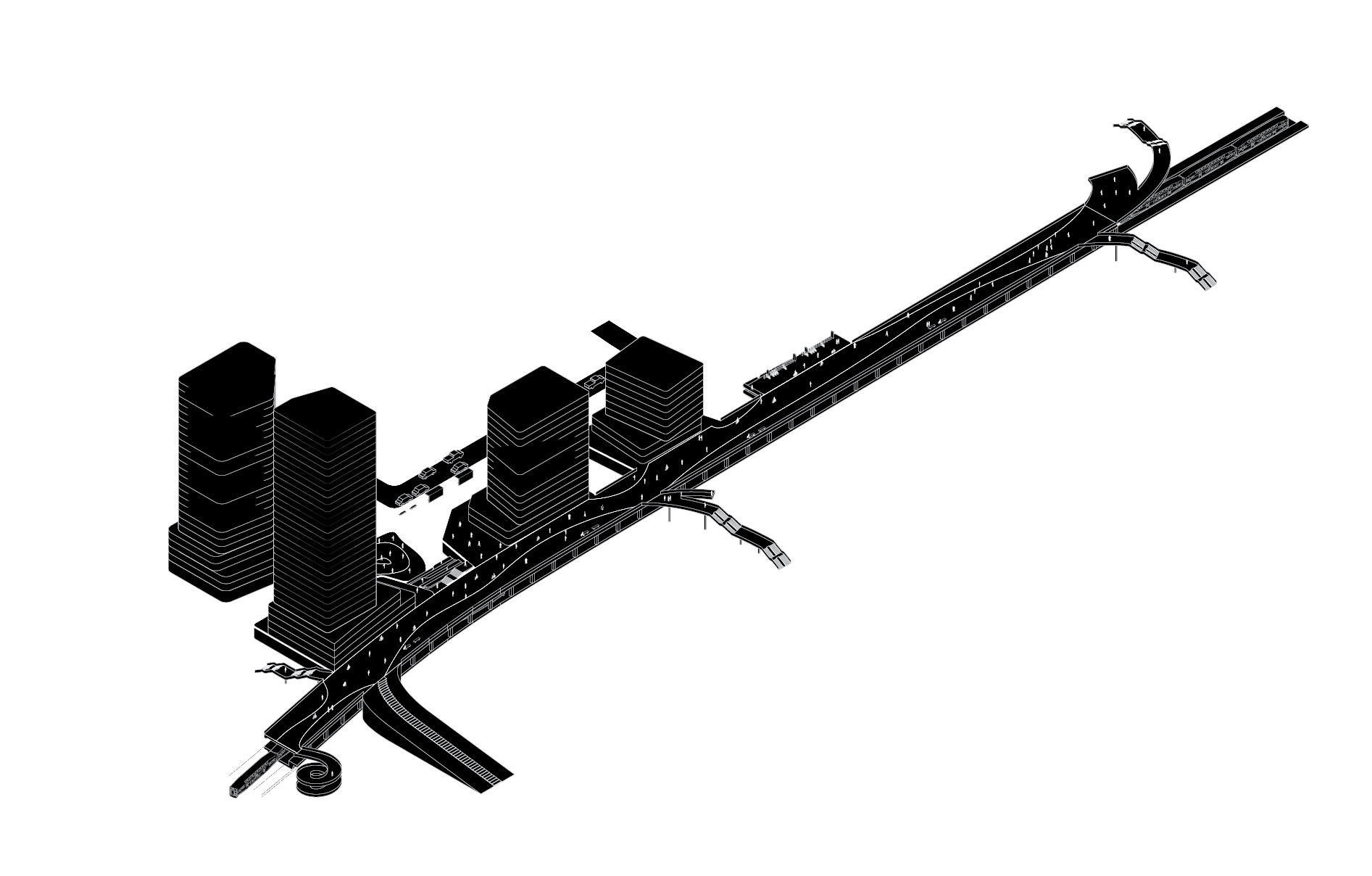

Re-purposing small-diameter trees as building components for carbon sequestration.Inverting the Unwanted introduces an innovative timber structure design that involves cutting a log into quarters and rearranging it to create a square exterior. This method standardizes the geometry and dimensions of small-diameter trees, which are an underutilized waste-material stream, transforming them into posts and beams. As small-diameter trees are often felled en masse as part of a forestry practice called “thinning”, repurposing these materials has the potential to sequester the carbon otherwise released through decomposition.

Click here for a full write up of the work.

Currently, this work is ongoing with the University of Nebraska Lincoln as part of a Design Build project schedule for completion Spring 2026.

Click here for a full write up of the work.

Currently, this work is ongoing with the University of Nebraska Lincoln as part of a Design Build project schedule for completion Spring 2026.

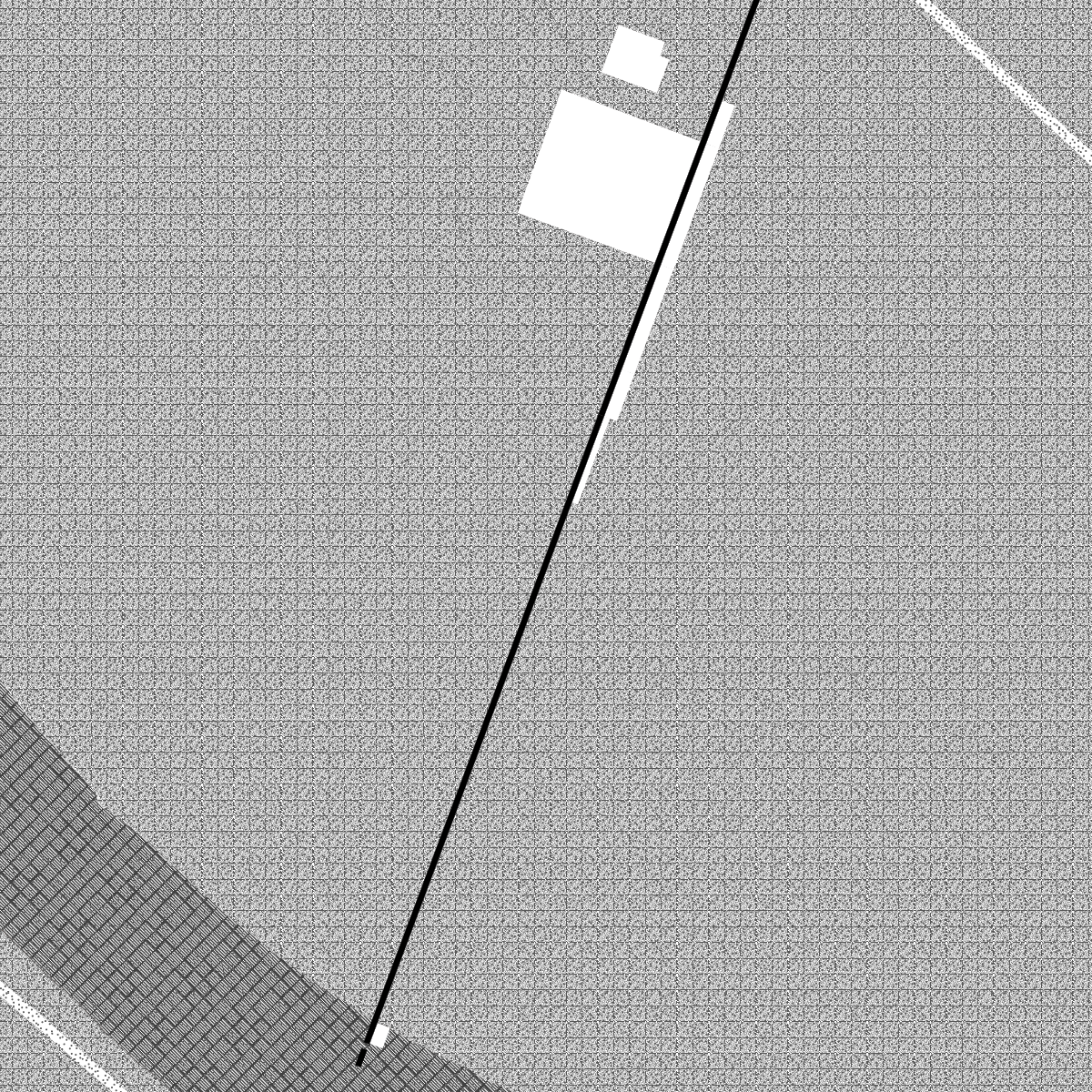

small diameter trees - an underutilized resource stream

A 1km x 1km stand of trees pre-thinning

A 1km x 1km stand of trees pre-thinning

Thinning

is a process where foresters cut down small diameter trees to funnel nutrients to larger ones.

The typical use cases are for pulpwood for paper manufacturing. These cut trees are not worth much, and after transportation/labor costs, foresters barely break even.

Most of the time, these cut trees are left to decompose, and all the carbon sequestered goes back into the atmosphere.

The typical use cases are for pulpwood for paper manufacturing. These cut trees are not worth much, and after transportation/labor costs, foresters barely break even.

Most of the time, these cut trees are left to decompose, and all the carbon sequestered goes back into the atmosphere.

Thinning includes a host of benefits, such as:

Reducing ladder fuels (small trees and understory that causes forest-fires to “climb” and light large trees)

Increasing available nutrients for mature trees

Prevention of “natural thinning”, when trees weaken due to a lack of nutrients and start to die, often spreading pest/disease

Reducing ladder fuels (small trees and understory that causes forest-fires to “climb” and light large trees)

Increasing available nutrients for mature trees

Prevention of “natural thinning”, when trees weaken due to a lack of nutrients and start to die, often spreading pest/disease

Post-thinning

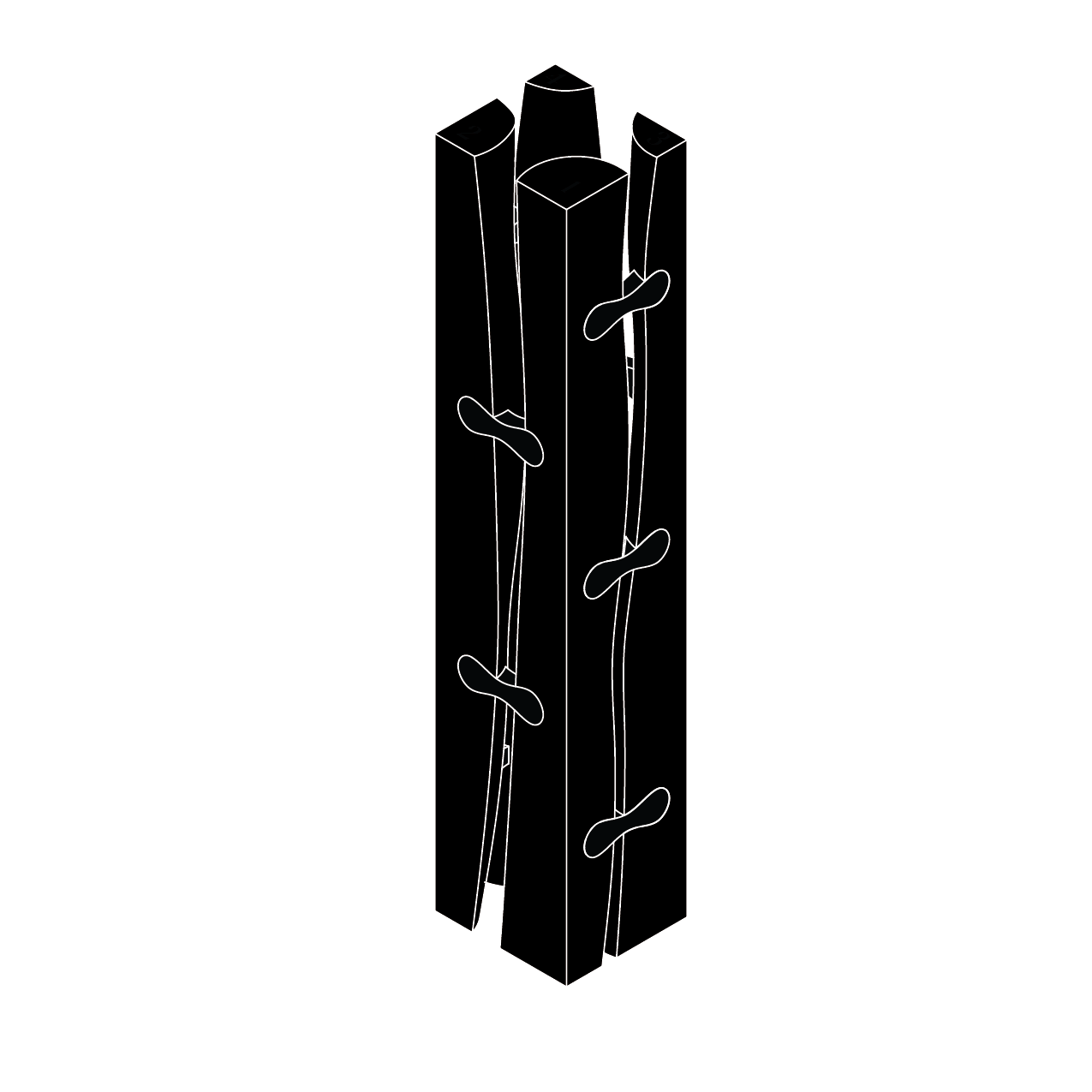

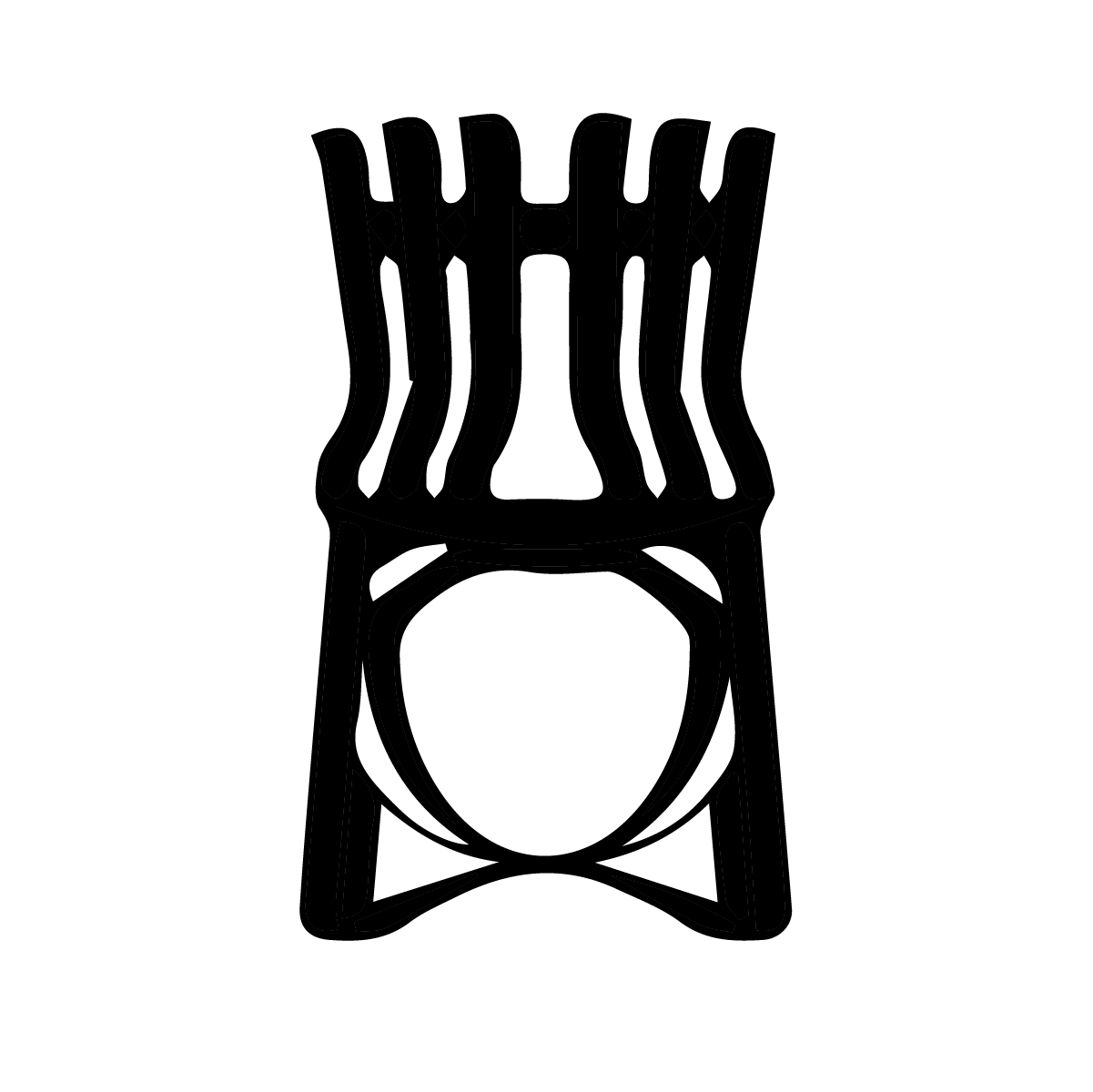

the puzzle log technique

An early sketch of the idea

The general

premise of this design is:

1. Cut a log into quarters

2. Rearrange the quarters so the square corners face outwards

3. Bind/join the quadrants

Key advantages:

1. Utilizes a cheap resource waste stream with maximal efficiency

2. Creates a square member for ease of construction

3. Leverages natural geometry and edge alignment for structural and aesthetic benefits

1. Cut a log into quarters

2. Rearrange the quarters so the square corners face outwards

3. Bind/join the quadrants

Key advantages:

1. Utilizes a cheap resource waste stream with maximal efficiency

2. Creates a square member for ease of construction

3. Leverages natural geometry and edge alignment for structural and aesthetic benefits

prototyping

prototyping

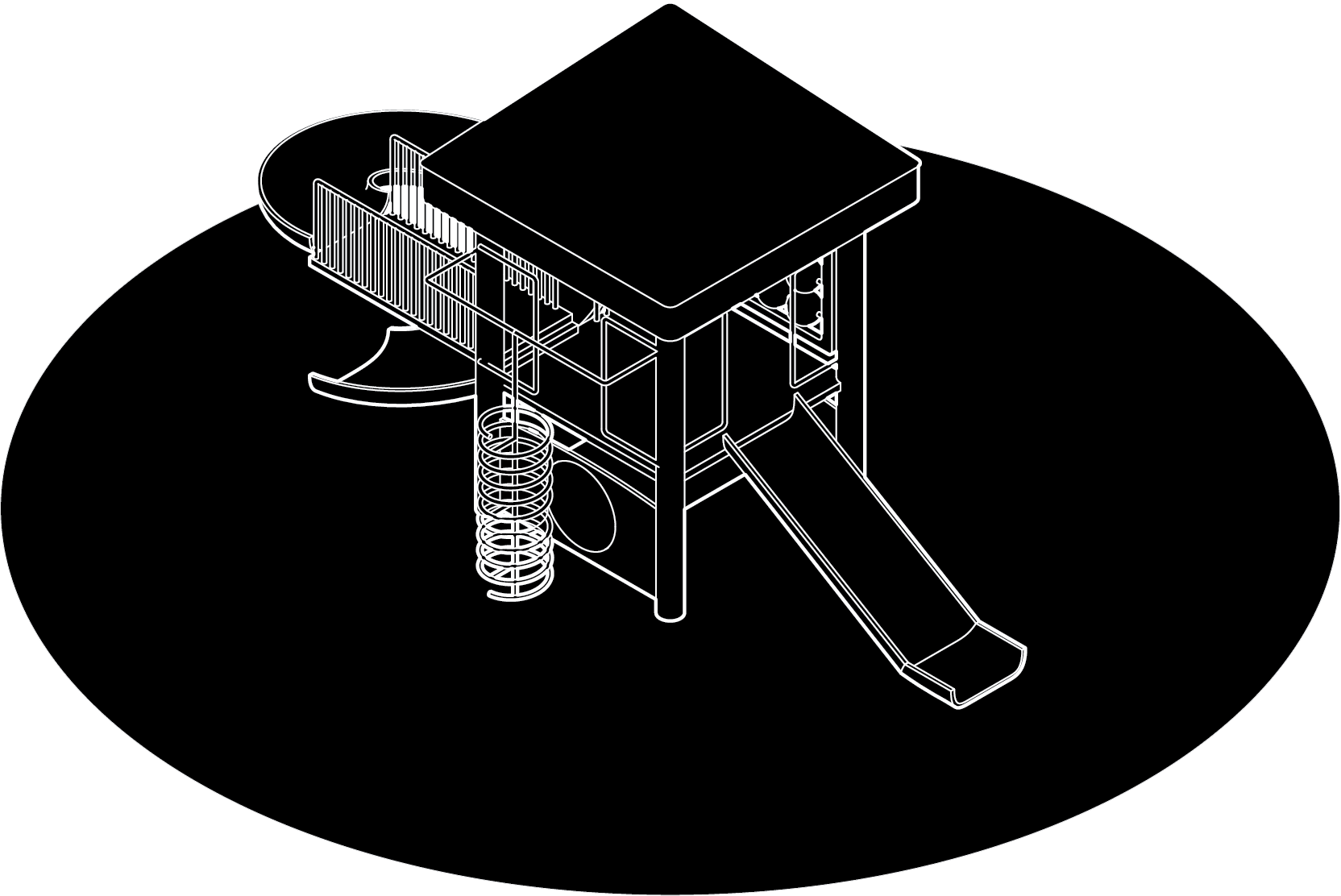

A total of 10 prototypes were designed and fabricated

Each prototype tests various joinery techniques, manufacturing processes, and computational tools

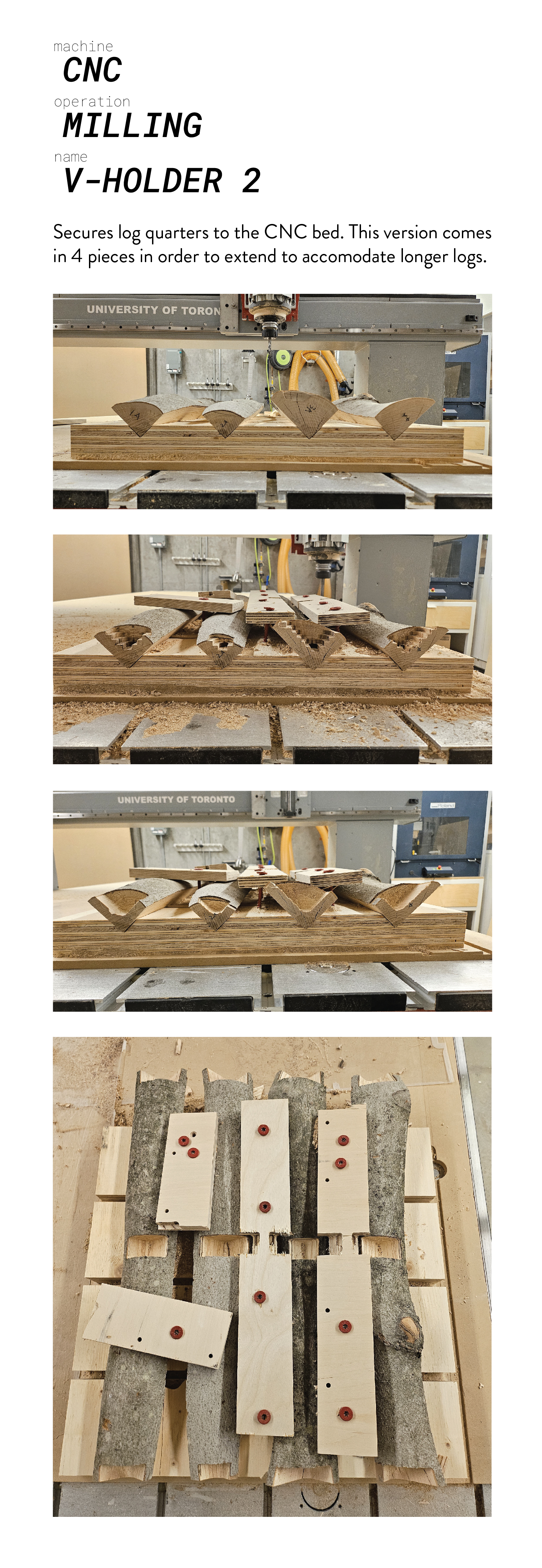

custom tooling

Custom jigs and tooling were necessary to fabricate and accomodate the uneven geometry of round logs.

A total of 15 jigs were built and used in the process of this project.

build process

computational processes

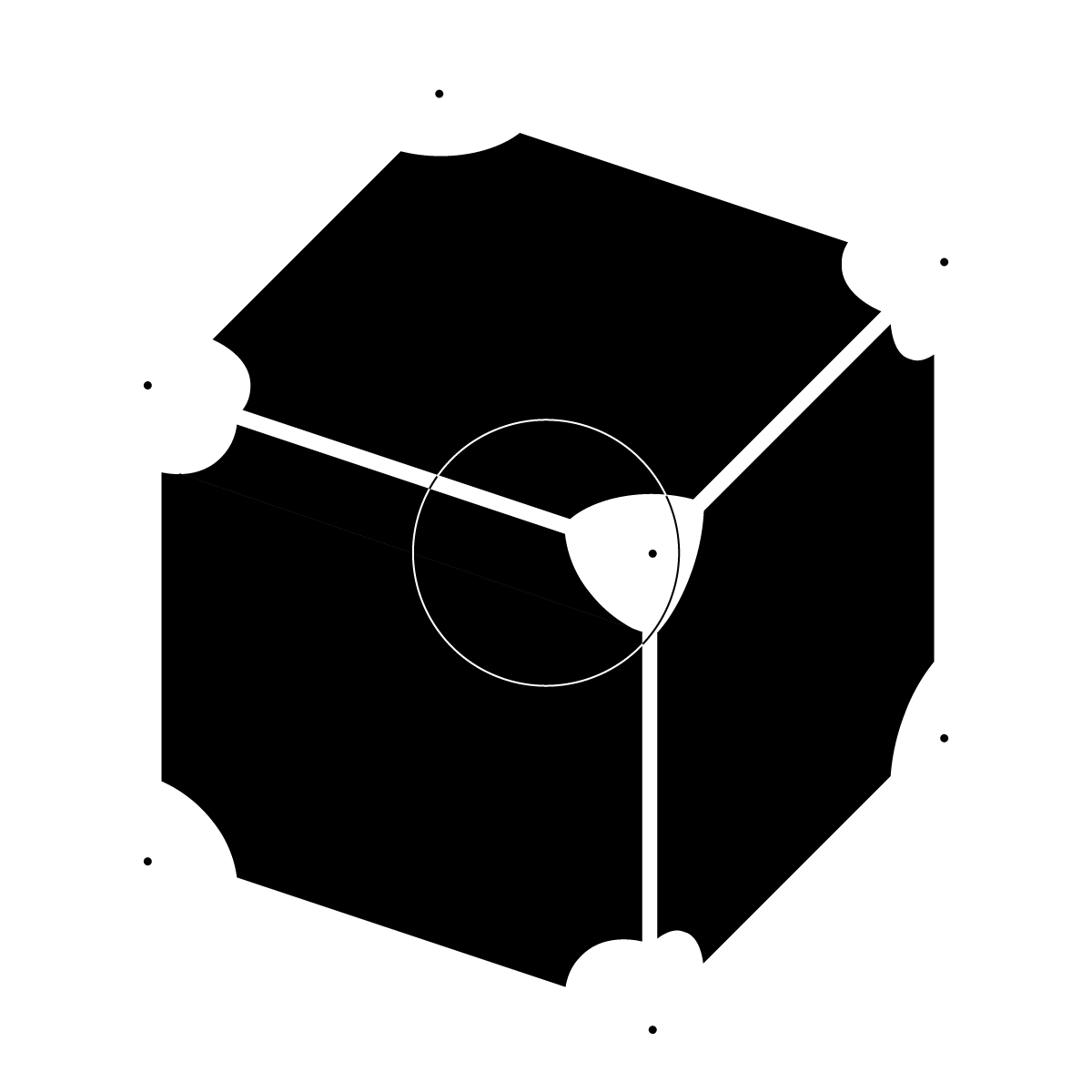

Computational tools and processes were key to the development of certain prototypes, and are a means to scale the work while keeping fabrication efficient. Key computational processes utilizes were:Genetic Optimization (Galapagos)

Photogrammetry

Pseudo-random recursion

Log of Best Fit

Computational techniques such as genetic optimization via Galapagos can be utilized to speed up the search for cut planes that define a structurally stable column. In the video shown, the script takes a scanned log and is optimized to minimize the volume difference between the cut quadrants. This balances wood mass amongst the column quadrants to distribute the load equally.

Fitness Criteria: Minimize difference in volume between quadrants

Genome: Cutting plane angle and position

While the optimization itself is still in its infancy, it produces rich possibilities for scaling up the production of the Puzzle Log. Furthermore, it helped explore the design space of the Puzzle Log, discovering new configurations previously unthought of.

Computational techniques such as genetic optimization via Galapagos can be utilized to speed up the search for cut planes that define a structurally stable column. In the video shown, the script takes a scanned log and is optimized to minimize the volume difference between the cut quadrants. This balances wood mass amongst the column quadrants to distribute the load equally.

Fitness Criteria: Minimize difference in volume between quadrants

Genome: Cutting plane angle and position

While the optimization itself is still in its infancy, it produces rich possibilities for scaling up the production of the Puzzle Log. Furthermore, it helped explore the design space of the Puzzle Log, discovering new configurations previously unthought of.

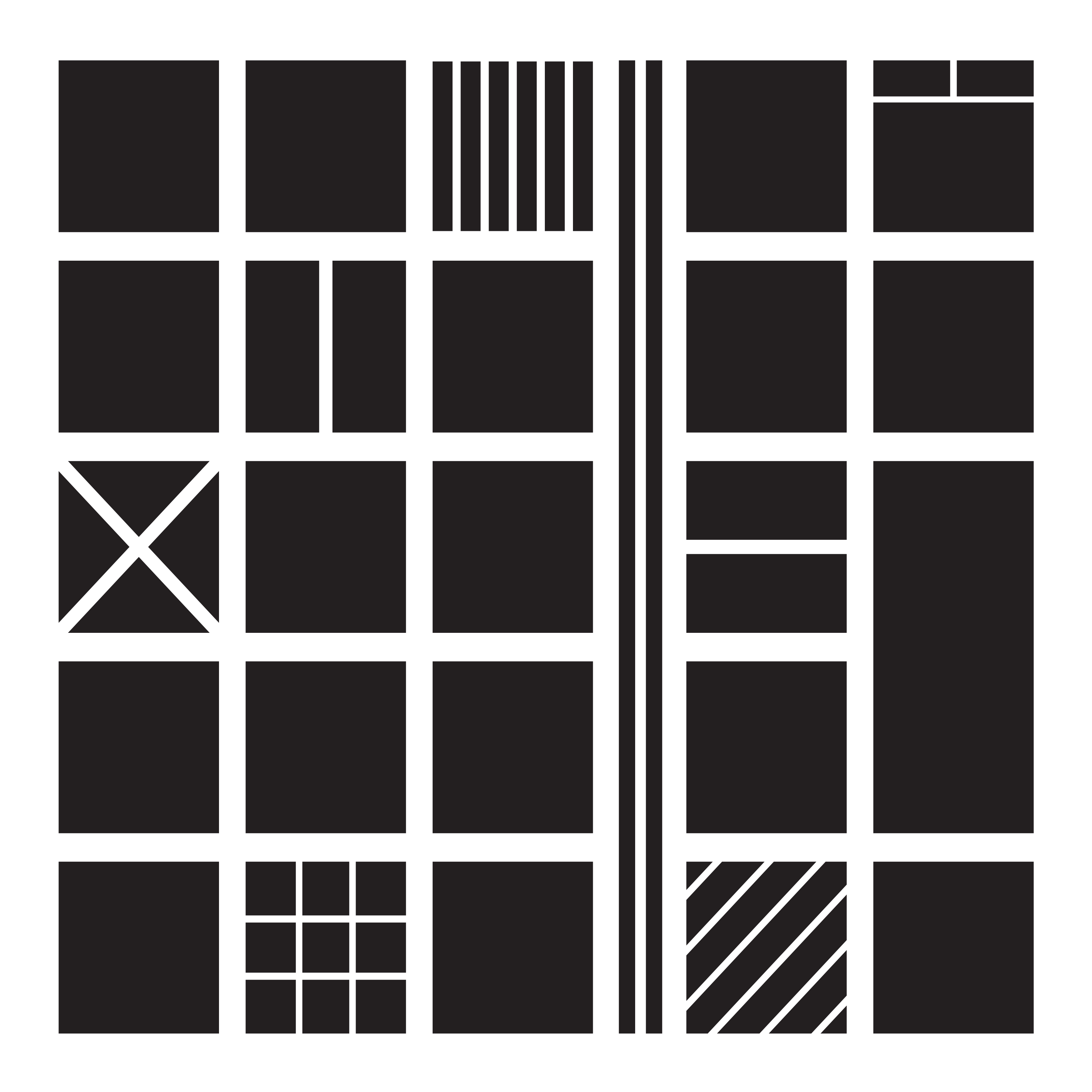

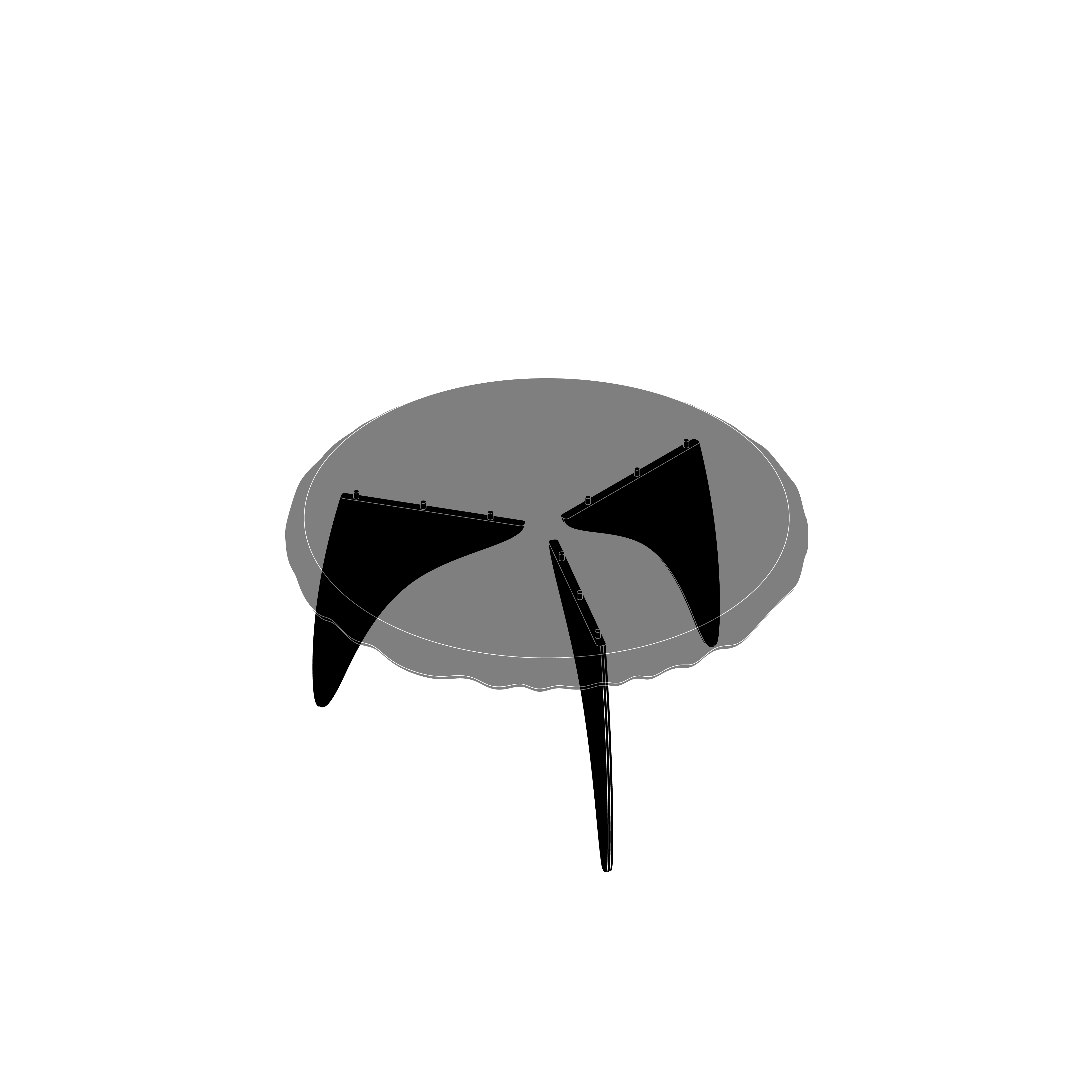

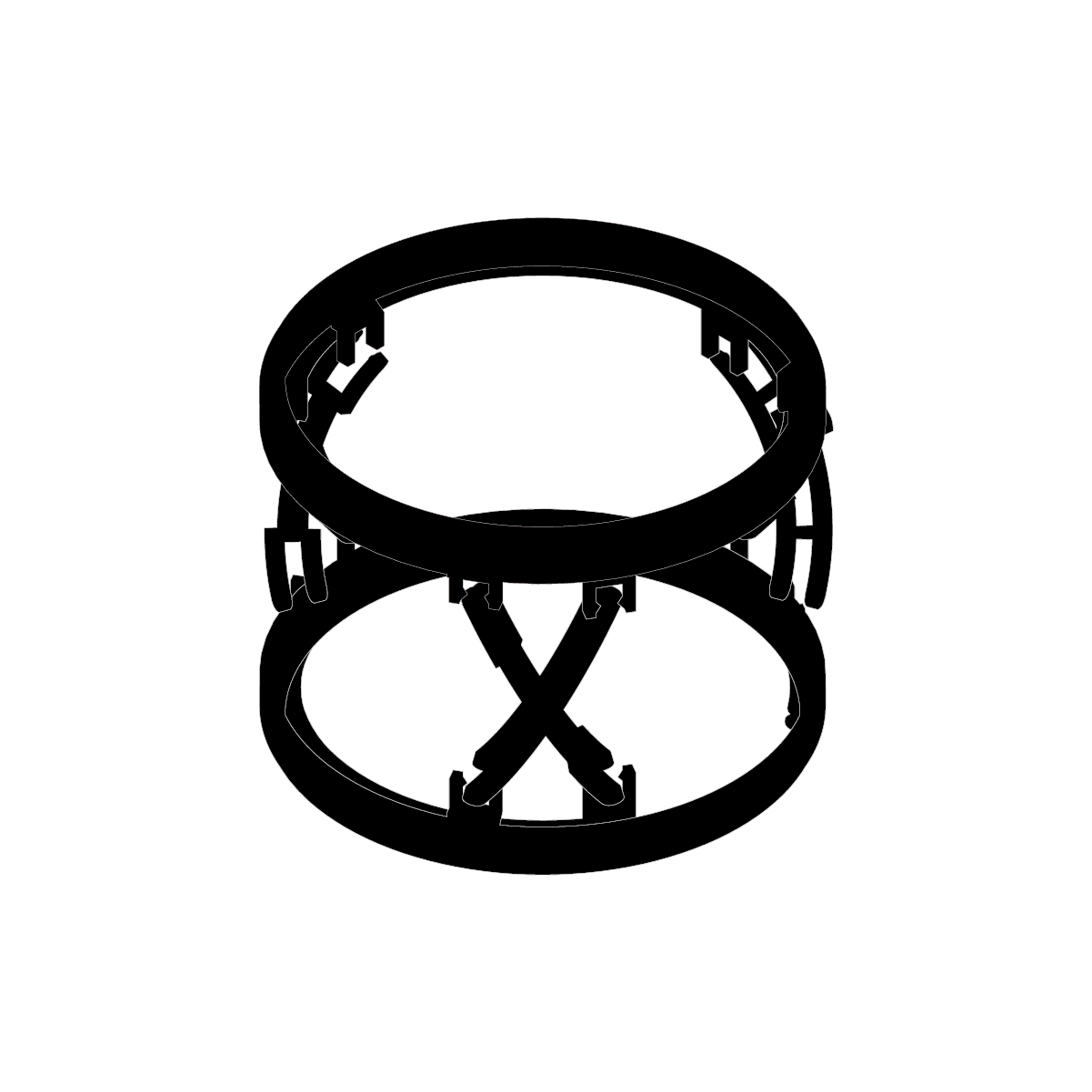

Log Generator

Log Generator is a grasshopper script that generates pseudo-randomized logs that auto-cuts and positions the quarters and inverts them to form the final product.

The randomization of log geometry and the cut planes ensures diversity in output generations somewhat reflective of the natural growth of trees. The randomization process includes multiple parameters that recursively produces a synthetic dataset of test logs.

This synthetic dataset was key to the further testing and development of connection details and structural drawings.

Log Generator is a grasshopper script that generates pseudo-randomized logs that auto-cuts and positions the quarters and inverts them to form the final product.

The randomization of log geometry and the cut planes ensures diversity in output generations somewhat reflective of the natural growth of trees. The randomization process includes multiple parameters that recursively produces a synthetic dataset of test logs.

This synthetic dataset was key to the further testing and development of connection details and structural drawings.

thesis exhibition